Premium Partner

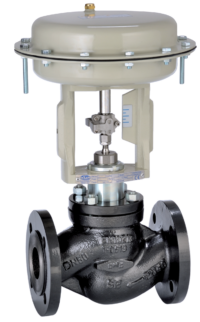

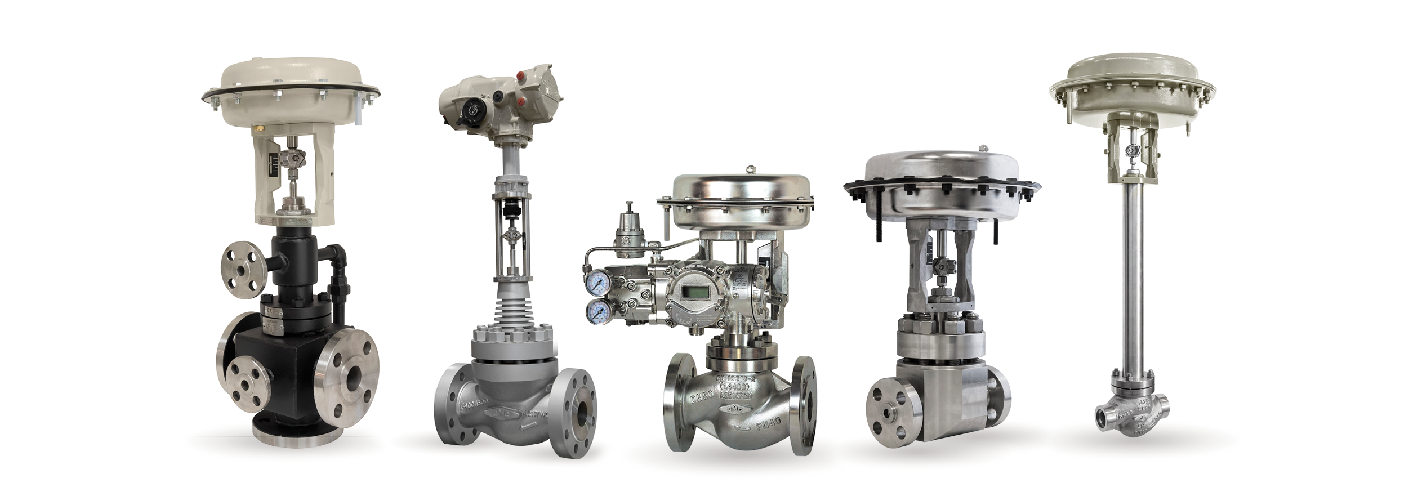

OMC VL 10 SERIES / AIR-D

OMC globe valve with screwed-in seat up to pressure rating PN 16

The VL10 series is a screw-in seat globe valve designed for light industrial applications up to pressure rating PN16.

The Air-D series is characterized by the fact that thanks to

of the clamped seat no special tool for the

maintenance work is required. Here, too, the pressure stage is limited to PN16.

The standardized options of the VL10 series make it ideal for general light industrial applications where process conditions require a simple control valve.

Technical data:

Nominal size range: DN 15 – DN 100

Pressure ratings:

PN 16

Housing material:

Spheroidal cast iron GGG40.3

Seat / Plug:

Equal percentage soft seal Class VI

OMC VD 10 SERIES

OMC globe valve with screwed-in seat up to pressure rating PN 25

The VD10 series is a globe valve with threaded seat designed for general applications up to pressure rating PN25.

These general applications include process events such as erosion, abrasion, corrosion, cavitation, and flashing that occur in most processes in industry.

Various options are available for type VD10, such as a valve bonnet with temperature extension, bellows seals, hardened sealing surfaces, soft-seated plugs, noise-reducing and anti-cavitation cages.

Technical data:

Sizes: DN 15 – DN 250

Pressure ratings:

PN 16 / PN 25

Housing material:

Spheroidal cast iron GGG40.3

Seat / Cone:

Equal percentage or Linear /

Shaft guided / reduced KVs values /

Sound reduction / anti-cavitation

OMC KD 20 SERIES

OMC globe valve with screwed-in seat up to pressure rating PN 100

The KD20 series is a screw-in seat globe valve designed for general applications up to PN100 pressure rating.

These general applications include process events such as erosion, abrasion, corrosion, cavitation, and flashing that occur in most processes.

Various options are available for type KD20, such as a valve bonnet with temperature extension, bellows seals, hardened sealing surfaces,

soft-sealing cones, noise-reducing and anti-cavitation cages.

Technical data:

Sizes: DN 15 – DN 200

Pressure ratings:

PN 63 / PN 100

Housing material:

Cast steel 1.0619,

Stainless steel 1.4408, Alloy Materials

Seat / Cone:

Equal percentage or Linear /

Shaft guided / reduced KVs values /

Sound reduction / anti-cavitation

OMC KD 10 SERIES

OMC globe valve with screwed-in seat up to pressure rating PN 40

The KD10 series is a screw-in seat globe valve designed for general applications up to the limits of pressure rating PN40.

These general applications also include process events such as erosion, abrasion, corrosion, cavitation, and flashing that occur in most processes.

Various options are available for type KD10, such as a valve bonnet with temperature extension, bellows seals, hardened sealing surfaces, soft-seated plugs, noise-reducing and anti-cavitation cages.

Technical data:

Nominal size range: DN 15 – DN 250

Pressure ratings:

PN 16 / PN 40

Housing material:

Cast steel 1.0619,

Stainless steel 1.4408

Seat / Cone:

Equal percentage or Linear /

Shaft guided / reduced KVs values /

Sound reduction / anti-cavitation

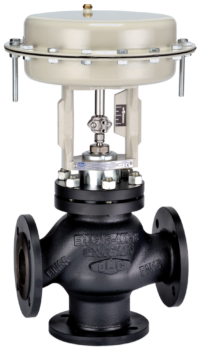

OMC TM 10 / TD 10 SERIES

OMC three-way valve with screwed seat up to pressure rating PN 40

The three-way valve with screwed seat type TM10 /TD10 is designed for general applications up to the limits of pressure rating PN40.

These general applications include both mixing(TM10) and dispensing(TD10) media in most applications.

The OMC three-way valve has several standard options such as temperature extensions, bellows seals and heating jackets.

Technical data:

Sizes: DN 15 – DN 200

Pressure ratings:

PN 16 / PN 40

Body material:

Spheroidal graphite iron (2x s), cast steel 1.0619, stainless steel 1.4408

Seat / Cone: Linear

Mixing valve or diverting valve

OMC RD 10 SERIES

Standard size self-contained OMC pressure reducing valve, suitable for all general industrial applications.

The automatic pressure reducing valve type RD10 is a standard size regulator suitable for all general industrial applications. A pressure reducing valve is used to control the downstream pressure to an adjusted set point.

A pressure reducing valve closes when the downstream pressure rises above a certain value.

The interchangeable drive enables simple and fast replacement, even on site.

Technical data:

Nominal size range: DN 15 – DN 100

Pressure ratings:

PN 16 / PN 25 / PN 40

Body material:

Ductile iron (2x s), cast steel 1.0619, stainless steel 1.4408

Seat / Plug:

Guided bellows design

Adjustment range:

from 0.1 to 16 bar

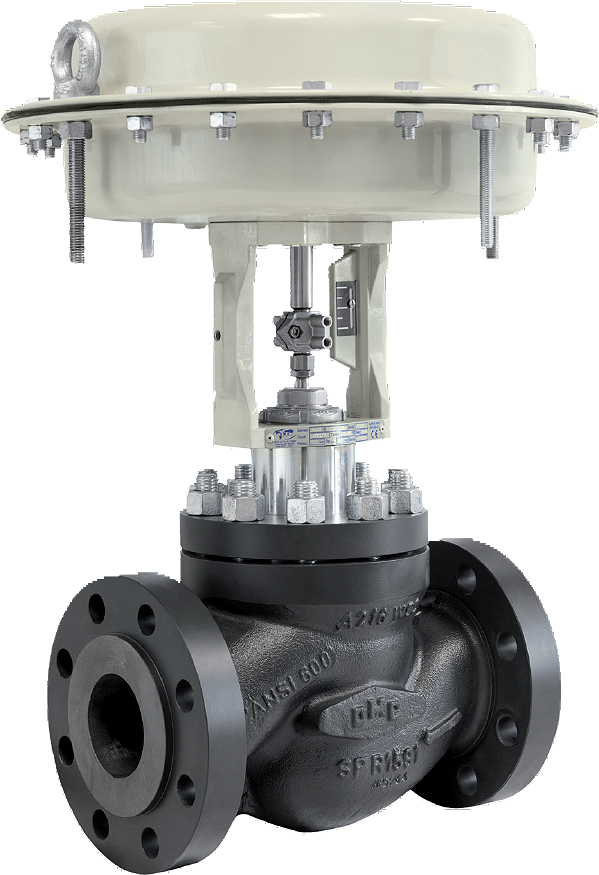

OMC KA 20 SERIES

OMC globe valve with screwed seat up to pressure class ANSI Class 600

The KA20 series is a threaded seat globe valve designed for general purpose applications up to ANSI Class 600 pressure rating limits.

These general applications include process events such as erosion, abrasion, corrosion, cavitation, and flashing that occur in most industrial processes.

Various options are available for the KA20 type, such as a valve bonnet with temperature extension, bellows seals, hardened sealing surfaces, soft-seated plugs, noise-reducing and anti-cavitation cages.

Technical data:

Sizes:

1/2″ to 8″

Pressure rating: ANSI 600

Body Material:

ASTM A216 WCC, STM A351 CF8M, Alloy Steel

Seat / Cone:

Equal percentage or Linear /

Shaft guided / reduced KVs values /

Sound reduction / anti-cavitation

OMC KA 10 SERIES

OMC globe valve with screwed seat up to pressure class ANSI Class 300

The KA10 series is a screwed seat globe valve designed for general purpose applications up to ANSI Class 300 pressure class limits.

These general applications include process events such as erosion, abrasion, corrosion, cavitation, and flashing that occur in most processes.

Various options are available for the KA10 type, such as a valve bonnet with temperature extension, bellows seals, hardened sealing surfaces, soft-seated plugs, noise-reducing and anti-cavitation cages.

Technical data:

Sizes:

1/2″ to 10″

Pressure ratings:

ANSI 150 / 300

Housing Material:

ASTM A216 WCC, STM A351 CF8M, Alloy Steel

Seat / Cone:

Equal percentage or linear / Shaft guided / Reduced KVs values / Sound reduction / Anti-cavitation.

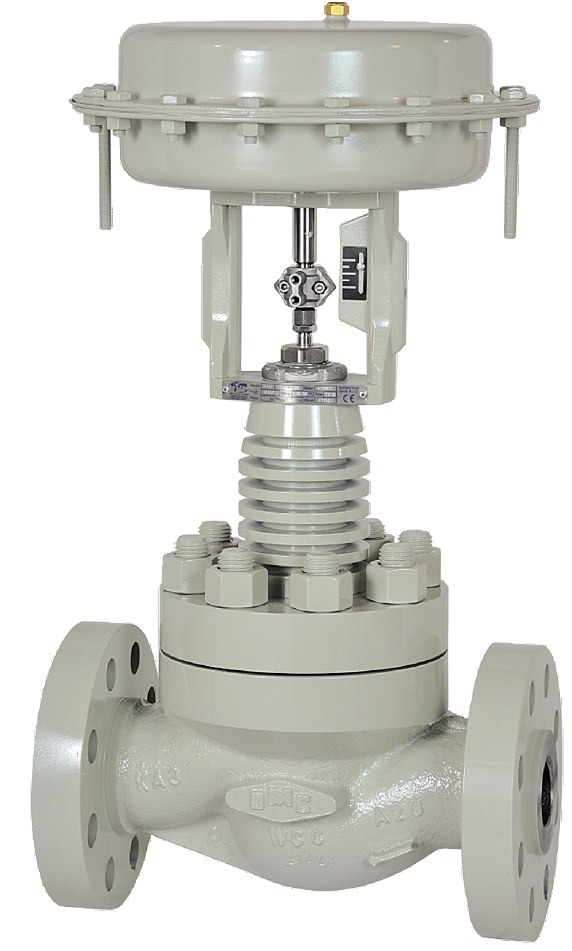

OMC KA 30 SERIES

Balanced OMC globe valve with screwed seat up to pressure class ANSI Class 900 / 1500

The KA30 series is a balanced globe valve with a threaded seat designed for high performance applications up to ANSI Class 900/1500 pressure rating limits.

These high-pressure applications include process events such as erosion, abrasion, corrosion, cavitation, and flashing that occur in most processes in industry.

Various options are available for type KA30, such as a valve bonnet with temperature extension, bellows seals, hardened sealing surfaces, soft-seated plugs, noise-reducing and anti-cavitation cages.

Technical data:

Sizes:

1/2″ to 4″

Pressure stages:

ANSI 900 / 1500

Housing Material:

ASTM A216 WCC, ASTM A351 CF8M, Alloy Steel

Seat / Taper:

Equal percentage or linear / Shaft guided / Reduced KVs values /

Sound reduction / anti-cavitation

OMC AM 10 / AD 10 SERIES

OMC three-way valve with screwed-in seat up to pressure class ANSI Class 150 / 300

The Type AM10 /AD10 threaded seat three-way valve is designed for general applications up to the limits of ANSI Class 300 pressure rating.

These general applications include both mixing(AM10) and dispensing(AD10) media in most applications.

The OMC three-way valve has several standard options such as temperature extensions, bellows seals and heating jackets.

Technical data:

Nominal size range: 1″ – 8″

Pressure ratings:

ANSI Cl 150 / 300

Housing material:

ASTM A216 WCC, ASTM A351 CF8M

Seat / Cone: Linear

Mixing valve or diverting valve

OMC RA 10 SERIES

Standard size self-contained OMC pressure reducing valve, suitable for all general industrial applications.

The self-acting pressure regulator type RA10 is a standard size regulator suitable for all general industrial applications. A pressure reducing valve is used to control the downstream pressure to an adjusted set point.

A pressure reducing valve is designed to close when the downstream pressure rises above a certain level.

The quick-change drive enables easy replacement, even on site.

Technical data:

Sizes: 1/2″ – 4″

Pressure ratings:

ANSI CL 150/300

Housing material:

ASTM A216 WCC, ASTM A351 CF8M

Seat / Plug:

Guided bellows design

Adjustment range:

from 0.1 to 16 barg

OMC S 100 SERIES

OMC hygiene S100 series control valves are made of AISI 316L stainless steel and are available in both two-way and three-way versions

The S100 series hygiene control valves are made of AISI 316L stainless steel and are available in both two-way and three-way versions.

These valves are designed for use with liquids, food, clean steam and pure steam. They are also used in the food industry to regulate and/or mix liquids and gases.

The valves can be operated with pneumatic or electric actuators for open-close or modulating control and can be equipped with various control systems, e.g. inverters and positioners.

Technical data:

Sizes:

1/2″ to 4″

Body material: AISI 316 L

Seat / Plug:

Equal percentage /

Linear reduced KVs values

Surface treatment :

Interior – 0.8 μ Standard 0.4 / 0.6 μ on request

Outside – 3.2 μ

SPECIAL FITTINGS

OMC control valves are designed for use in the most diverse processes

available. The wide range of options allows them to be used even with more difficult

Control tasks are used

OMC control valves are available for use in a wide variety of processes.

The wide range of options means that they can also be used for more difficult control tasks.

Thanks to the selectable valve bonnets and stem sealing systems, temperatures from the

Cryogenic range -196 °C up to high temperature range +600 °C possible.

A wide range of materials from normal steel to various stainless steels and special materials such as Duplex, Superduplex, Monel, Hastelloy also allow use in many chemical areas as well as food and pharmaceutical sectors.

The choice of different external coatings of the valves allows them to meet a wide range of requirements due to more difficult environments.

OPTIONS

Surface treatment

All housing parts manufactured at OMC receive an acrylic primer and are then finished with a 2-component acrylic lacquer.

Optionally, however, a customer-specific surface treatment can also be offered. The drive shells are galvanized and then

coated on both sides with an electrostatic powder coating.

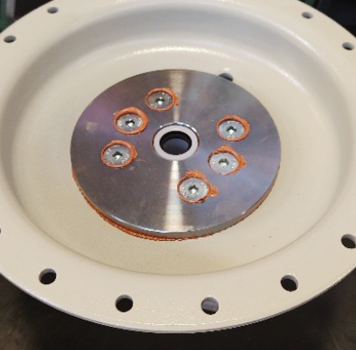

Positioner

The positioner is one of the most important elements of a control system. It receives the control signal (4…20 mA) from the controller and converts it locally. The user decides whether a digital microprocessor-controlled controller should be included in the scope of delivery or a solution with a conventional nozzle/ flapper system.